No matter what type of welding you do, you need to lay a good weld to give it the best strength. A bad weld will weaken the structure and possibly cause a catastrophic failure.

Identifying a bad weld gives you the chance to fix the problem before it becomes an even bigger problem in the future. The following will help you to know how to identify the most dangerous defects that could weaken your weld.

In This Article

How to Inspect a Weld for Defects

You need to see beneath the surface of a freshly laid weld before you can identify any defects that it might contain. Some defects are obvious at the surface, but some of the most dangerous lie just beneath it.

A grinder is the most convenient tool for exposing the inside of a weld. You just grind off a portion of the top of the weld to get a good look at what is inside.

You also might use a cutting disc to cut off a portion of the weld at the top so that you can inspect it. You could use the pointed end of a chipping hammer to help inspect the weld for tiny imperfections and test its strength.

Types of Bad Welding

The following are seven of the most common and most dangerous weld defects and how to correct them.

1. Incomplete Penetration

A weld should penetrate to the bottom of both pieces of metal without blowing a hole through them. When a weld does not penetrate fully, it is weak and prone to breaking.

Incomplete penetration occurs when the heat is too low, you go too quickly, or both occur while you are laying the weld.

The defect usually causes a space or small gap at the bottom of the weld. It also prevents proper fusion.

You can check the underside of the metal to determine if the weld penetrated fully. If you do not see a line of slightly deformed metal underneath, the weld does not go in deep enough.

Grinding out the bad weld and laying a new one using the correct heat and timing will fix the condition.

2. Cracked Weld

A cracked weld has an obvious flaw that clearly weakens the entire structure. Enough stress on the weld could break it and cause the metal to separate.

Contaminants, fast cooling, and an incorrect ratio of width to depth could cause the weld to develop tiny cracks. The cracks might run lengthwise, across the weld, or create small craters.

You can correct it by grinding out the weld or using a carbon arc to gouge it out. Then you can pay a better weld.

3. Undercut

An undercut occurs when the filler rod does not completely fill the weld and leaves a groove in the metal.

Although you get full fusion and good penetration, the defect could cause cracking if it becomes fatigued over time. The cracking could trigger a weld failure.

The welding technique is the primary cause. Too much heat along the edges, erratic movements while welding, and holding an arc that is too long are common causes of an undercut defect.

You can remove the weld and lay another one while using a better welding technique to fix the problem.

4. Slag Inclusion

Most types of welding produce slag as a byproduct. That slag often winds up on the surface where you can chip or scrape it off while the metal is still hot.

Sometimes, the slag becomes mixed with welded material in small pockets. The slag inclusion occupies space that should contain metal from the filler rod.

Slag inclusion could happen at just about any time. So it is important to thoroughly clean and inspect the weld after every pass so that you can prevent as much slag as possible from getting into the weld.

Frequent inspection and keeping the weld clean after each pass can help to spot the problem early. Then you can scrape, grind, or brush the slag from the weld and run another one over it.

5. Incomplete Fusion

The weld must fuse completely with the base metal to be fully effective. When the weld does not completely fuse with the base metal, it will leave empty, weak spots within the weld.

The empty spaces weaken the weld and make it prone to failure.

Laying the weld too fast, using an improper angle with the rod, or incomplete melting of the base metal or weld are among its many causes.

The fix is the same as most other imperfections. You need to remove the weld and lay a new one.

6. Porosity

A weld sometimes could contain tiny cavities that make the weld weak and prone to damage.

The pores in the metal might be distributed throughout the weld or have pores that break the surface of the weld. Porosity also might cause wormholes and crater pipes that run through parts of the weld.

The problem often happens due to oil, grease, or other contamination of the metal you are welding. If the metal has a surface coating, that also might cause porosity.

A grinder is the most effective tool for removing the defective weld so that you can lay a correct weld in its place.

7. Spatter

Spatter is one of the few imperfections that do not weaken the weld. Instead, the welding rod spatters tiny bits of molten metal onto the base metal next to the weld.

A poorly connected ground clamp, an overly hot or cold weld pool, and a dirty or contaminated welding surface are some of the many potential causes.

Fortunately, you can grind off the spatter very easily and leave a smooth surface.

Preparation Helps to Prevent Imperfections

Ultimately, most welding defects are preventable. It starts with cleaning and prepping the metal correctly and using your best welding technique to lay a good bead.

Then you need to ensure you are using quality welding rods and flux and properly clamp the ground.

Once everything else is in ideal condition for welding, you need to use your best technique to lay a good, consistent bead that creates the perfect weld.

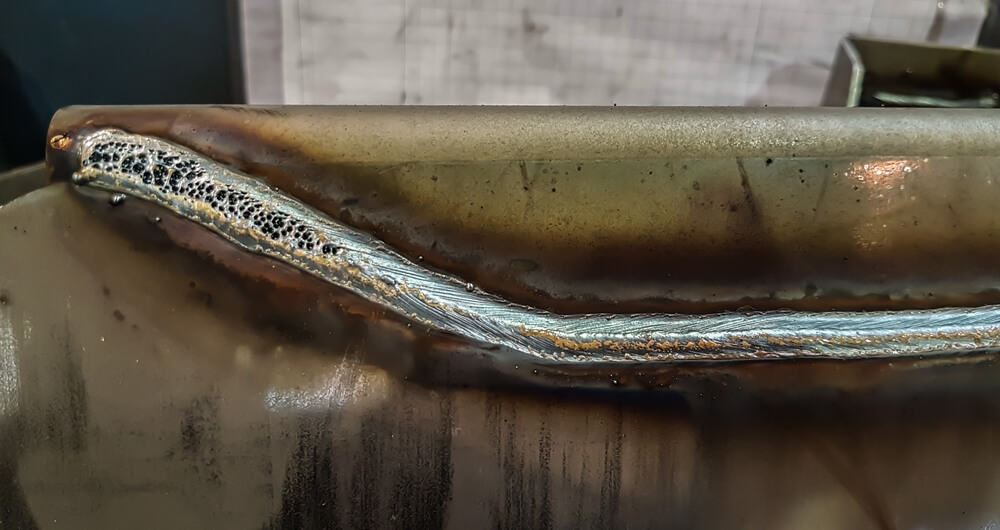

Bad Welding Pictures & Examples

Here are some specific examples of bad welding in pictures:

An example of a bad weld with a seam separating:

And another example of a poor weld job:

Frequently Asked Questions

There are several ways to tell if a weld is bad. First, check for cracks. If there are any cracks in the weld, it is likely that the weld is bad. Another way to tell if a weld is bad is by looking at the color of the weld. If the weld is discolored, it is likely that the weld is bad. Finally, check for voids. If there are any voids in the weld, it is likely that the weld is bad.

Additional Sources & Resources

1. “Welding Defects.” Encyclopedia Britannica, https://www.britannica.com/technology/welding/Welding-defects.

2. “Types of Welding Defects.” TWI – Global Leaders in Welding and Materials Joining Technologies, http://www.twi-global.com/technical-knowledge/faqs/welding-faqs/types-of-welding-defects/.

3. “The 7 Most Common Types of Welding Defects Explained.” Welder Source Blog, http://blog.weldersource.com/the-7-most-common-types-of-welding-defects-explained.

4. “7 Frequently Asked Questions About Welding Defects.” EWI, http://www.ewi.org/news/blog/7-frequently-asked-questions-about-welding-defects/.

5. “Welding Defects – Causes and Cures.” Wemanage, https://wemanage.com/welding-defects/.

6. “Welding Defects: Causes & Cures (With Diagram).” Mechteacher, https://www.mechteacher.com/welding/welding-defects/.