Every welding machine is limited in terms of the thickness it can penetrate in a single pass. Extremely thick materials pose a problem for professional welders and hobbyists alike. One of the many solutions we have for this is the bevel weld. Here, we will discuss what a bevel weld is, when to use it, and more.

In This Article

What is a Bevel Weld? Use Guide, Overview, Symbol, & Callout

In welding, a bevel is an edge preparation presented as an angle. In cases where this type of weld must be made, the welder will make or be presented with a V-shaped groove in the gap between the two pieces of material. The purpose of this groove is to give the welder access to a larger surface area to which the weld can become affixed.

Supposing you have two thick pieces of material that need to be welded together, but you know that your machine will not penetrate the material and will leave an unattached portion beneath the weld. For this, you will create a bevel or a V groove. This is done by chamfering one or both pieces of material. Either way, you will then create a bead that fills the partial gap or valley between the two pieces of material and creates a solid joint between them.

Without this material preparation, the weld produced might be only on the surface of the two pieces of material, leaving a weak and incomplete joint. If you complete a weld on two such pieces of thick material without a beveled preparation, you might be able to see that on the reverse side there is a groove or a gap that is not welded. When making a second pass on the opposite side is not an option, a bevel preparation may be made.

The Bevel Weld Vs the V Weld

As mentioned above, we can create a chamfered edge on one or both pieces of material. A bevel weld is typically done with one chamfered piece of material. A V weld is done when both pieces of material are chamfered. If you were to look down the channel of both types of preparation, the V weld would look like a wide V with equally angled-out sides and the bevel weld would look like a V with one vertical side and one side at an angle.

The Bevel Weld Symbol or Bevel Weld Callout

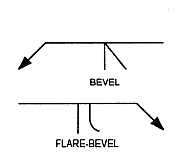

In professional settings, and in cases where a hobbyist kit is partially set up for aftermarket assembly, the welder may be presented with a bevel groove to be welded as described above. In instances like these, we should see documentation that uses welding symbols indicated for specific joints. This kind of documentation is meant to prompt the welder to use the best type of weld for a specific joint. The bevel weld symbol looks like the leaning V described above and is referred to as the bevel weld symbol or callout.

In some cases, the welder will see a symbol that indicates the joint needs to be chamfered. When an edge needs to be chamfered or a bevel needs to be created, you will see a two-angled arrow symbol that cranes over the gap in the joint at an inverted 40-degree angle.

Beveling vs Chamfering

A chamfer or a bevel is an edge transition between two object faces to be welded. Typically, an edge is square. To perform a bevel weld, we will need to create a bevel or a chamfer on one (Bevel weld) or both (V weld) of the edges.

- Chamfering: A chamfer takes a corner off of the edge of a piece of material. When it is done, you are left with two more obtuse angles for a softer edge. A chamfer is more shallow than a bevel and does not go through the entire thickness of the material.

- Beveling: A bevel is a deeper cut, going all the way through the material. When a bevel is made, we have two edges like we did when we started, but the upper edge is less acute and the bottom edge is more acute. A bevel is deeper than a chamfer and goes through the entire thickness of the material.

When a Bevel Weld Should Be Performed

A bevel weld is done when a welder is instructed to do so, either by direct instruction or by a symbol or callout in the job documentation. A bevel weld is a design for a welded joint. There are many types of joints and they are meant to work within the scope of a complete project to obtain the structural integrity the finished product needs.

An experienced welder may decide to perform a bevel weld on his own, but in most cases, the joint will be designed ahead of time by an engineer.

Suppose, for example, a welder is presented with two pieces of material that need to be jointed, but these pieces are in place on a larger structure. The welder cannot see or access the opposite side of the joint. He cannot complete the weld on the opposite side, or even see that there is a potential for incomplete penetration. This is an instance where a bevel should be made and the welder should be instructed either directly or through documentation to fill the gap using a bevel weld.

Other instances where a bevel weld should be used include any situation where the material is too thick and only one pass can be made.

Comparing the Bevel Weld to The V Groove

The V groove fits similar use cases as the bevel groove. The difference is that in a V groove, both opposing pieces of material are beveled or chamfered. This is why the symbol is an equal-sided V shape in which both sides angle out.

The V groove callout is a straight line over the joint diagram with an arrow angled at one point, indicating the un-beveled joint edges and a 40-degree angle marker under the upper line of the arrow.

The difference between these two types of joints is the thickness of the material at the bottom of the gap. At the base of the V, there is a thin layer of material that forms the bonding layer. Conversely, there is a much thicker layer at the top of the gap. If we weld this gap properly, the bond will be good all the way through the weld.

The V bevel, by comparison, does not leave as much room for error. A V bevel also takes more material to fill, which can increase work time and welding costs. For this reason, a single bevel weld is usually preferable to a V weld.

Frequently Asked Questions

Bevel welds are typically used when two pieces of metal need to be joined at an angle. This type of weld is also commonly used in situations where one piece of metal needs to be attached to another piece that is already in place.

Yes, a bevel weld is a type of groove weld.

Bevel welds are often stronger than fillet welds, due to the increased surface area that is fused together. Additionally, the angle of the bevel can add additional strength to the joint.

A single bevel groove weld is a type of weld that is made by joining two pieces of metal together at an angle using a single continuous bead.

The degree of the bevel will depend on the specific application. However, common angles for bevel welds are 30, 45, and 60 degrees.

Bevel welds offer several benefits, including increased strength, improved aesthetics, and the ability to attach metal to already existing structures.

The size of the bevel weld will depend on the thickness of the metal being joined and the desired strength of the joint.

The strength of a flare bevel weld is typically determined by performing a tension test on a sample weld. This test measures the amount of force required to break the weld.

Additional Sources & Resources

-http://www.engr.sjsu.edu/~mechano/welding/BevelWelds.htm

-https://www.tulsaworld.com/business/local/bevel-up-or-bevel-down-which-way-should-you-weld/article_cf6f35b2-3a24-11e7-9ed0-c3d07eaec4b8.html

http://www.thefabricator.com/article/arcwelding/getting-a-handle-on welding bevel types and configurations

http://hyperphysics.phy-astr.gsu.edu/hbase/Weld/weld.html

https://www.fierermetals.com/welding-bevels/

https://www.lincolnelectric.com/en-us/support/know-how/pages/types-of-joints-in-welding.aspx

https://www.millerwelds.com/resources/article-library/arc_welding_basics_different_types_of_joints

https://blog.ewiworks.com/the-importance-of-a-precisely-cut bevel angle in welding

http://www.wcWelding.org/PDFs/OERB%20-%20Weld%20Joint%20Geometry.pdf

https://www.jwDonovan.com/welding-resources/ gas tungsten arc welding bevel types

https://www.everyspec.com/MIL-SPECS/MIL-SPECS-MIL-W/download.php?spec=MIL-STD-248D.2217&tab1=scope&tab2=#2482 Standard Terminology Relating to Welding, Brazing, and Nondestructive Examination – Bevel angle (taper angle)

https://www.azosensors.com/article.aspx?ArticleID=1127 A Review of Ultrasonic Welding Techniques for Polymeric Materials – Bevel angle

http://www.prairiecat.net/client/en_US/default/search/detailnonmodal/ent:$002f$002fSD_ILS$002f0$002fSD_ILS:433573/ada WELDING TERMINOLOGY – BEVEL ANGLE

https://www.ndt-ed.org/EducationResources/CommunityCollege/Ultrasonic/Terminology.htm Ultrasonic Testing Terminology – Bevel Angle or Beam Angle

http://www.scielo.br/pdf/bjpmech/v42n4s1/_07-Bevel_angles_in_butt_weld